| Author |

Replies: 8 / Views: 671 Replies: 8 / Views: 671 |

|

|

Valued Member

195 Posts |

|

|

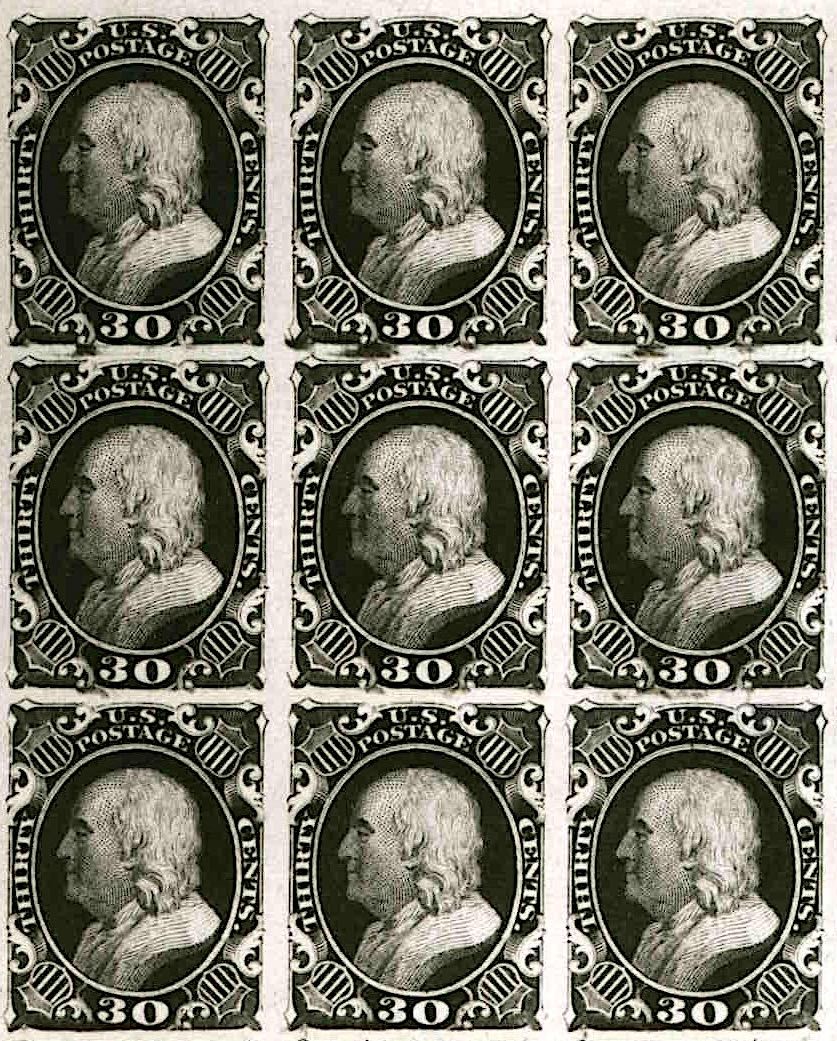

Hello Unkjay! Your willingness to participate here and share your knowledge is a gift which I'm sure many philatelists thought they'd never receive. It is a privilege to have an opportunity to ask you questions, and the generosity of your time in answering questions so far is duly, triply, and quadruply noted! I'd like to ask if you might be able to shed some light on some markings found between rows of stamps produced between 1851–60. Of course, these were made before your time, and before there was even a BEP! But given your experience, I was wondering if you might shed some light on how these markings came to be. Attached is one example where such markings can be seen; it's an excerpt from an archival photo of a plate proof taken from the right pane of the 30¢ of 1860. You can see that there is smudging below certain subjects and not on others. And a study of all 200 subjects shows that no two smudges are precisely alike. To my question: from your experience, do you think these marks may have been impressed on the plate when the design was transfered from the transfer roll? Or, might they reflect burnishing of the plate itself? Any insights you might be able to share would be most appreciated!  |

|

Send note to Staff

|

| Edited by essay_proof - 05/29/2023 04:46 am |

|

|

|

|

Valued Member

United States

153 Posts |

|

|

You are referring to the smuggling between stamps. They are not from the plate itself or intentional. They look to be from an area that was not cleaned of resin or gum. Resin or gum was used to protect the plate from rusting. It also can be from dust that may have settled in the lowest points of the sign. The dust could have compacted in those area from the pressure of the printing process. It is possible a lower area of the design formed from the manufacturer of the plate itself. I noted the design itself was not affected only the gutter between stamps. The early days of printing from flat plates this was common.

When printing from an engraving plate the image must be cleaned from time to time. If you do not clean the plate and reink you will have imperfections. In this case a smug. In short my best guess is the resin or gum used to protect the plate was not clean from those area and picked up a small amount of ink and transferred that to the print surface. No matter the root cause be it resin, gum, dirt, dust the plate needs cleaning. What ever it was the pressman did not take the time to clean the impression area very well.

I hope this answers your question with my best guess.

|

Send note to Staff

|

| Edited by Uknjay - 05/29/2023 07:50 am |

|

|

Valued Member

United States

153 Posts |

|

|

After thinking about the smudges for a minute. As these were new plates to make a sample. The smudges could come from the wax used to protect the plate in the engraving process. Wax is used to coat the plate and the engraver uses their cutting tools to etch the surface. The wax will protect the surface from any unattended scratches. If wax is in that area the ink would pick it up. It all comes back to not cleaning the plate very well. After the engraving is completed and resin or gum is applied it would run over the wax that had not been cleared from the face of the plate. This giving a substructure for this imperfection. |

Send note to Staff

|

| Edited by Uknjay - 05/29/2023 08:12 am |

|

|

Valued Member

Switzerland

333 Posts |

|

|

Uknjay: Are you confusing a few things?

Flat plates were not "engraved by an engraver."

Here is the sequence what happened (as far as my knowledge goes, I may be wrong, of course).

1. A soft steel plate was polished and placed into the "plate making machine" (whatever the thing was called).

2. A Siderographer entered weak layout dots, arcs and lines onto the soft steel plate. This was done to help place the die transfer roller to the correct spot.

3. The siderographer entered the stamp design onto the plate, usually 180/200/360/400 subjects per plate. This was done by placing the die transfer roller above the correct spot, and then rocking back and forth the die on the die transfer roller. This rocking back and forth was done multiple times with increasing pressure. Notice two things: First, impressing the master die with a single pass would have likely microcracked the plate, as enormous pressures were applied. Second: This technically is not engraver's work, as no steel is removed from the soft plate. It is actually "shifting aside" some soft steel by the die to create holes and grooves. The "shifted aside" steel would form very tiny bulges next to the grooves as it obviously had to go someplace.

4. When the siderographer was done, a plate finisher had to remove the layout dots, arcs and lines (unless they became part of the design by clever placement). The siderographer also had to polish the plate once again, in order to remove the tiny bulges made by the "shifted aside" steel.

5. Now the plate had to be checked for faults and a certified plate proof was made (probably on a flatbed spider press). Any smudges on the proof sheet were the result of bad plate wiping (which was not easy on a still soft steel plate).

6. If the plate was ok, it was hardened. Also the plate may have been chrome plated to further strengthen the surface against abrasion.In the early days, inks often contain minerals thsat could be very abrasive to the steel plate.

7. I don't know the sequence of proofing - hardening - chrome plating, it could have been any order (?).

8. When the plate proof sheet was certified, the plate went to the press. records show there is usually a one day gap between plate certification and start of printing. If don't think the plates were waxed for these few hours in between.

8. When the four plates were removed from the power press and went into storage (for additional possible print runs), they might have been covered with wax to protect them from rusting. I have never seen that mentioned in an article but it makes sense.

For rotary plates, I actually would like to know the following:

In articles, it is often written "plates needed to be curved" for the Stickney press.

Now what exactly was "curving?" It can be two things:

1. Two flat plates were fastened onto the drum of the Stickney press. They are curved by the drum.

2. Two flat plates were curved (with some machine tool) to have the radius of the Stickney drum. The curved plates were then fastened to the Stickeny drum. Also are the plates curved first, then hardened or are the plates hardened before curving?

The result is the same, but the difference is that:

In case 1, the plates are forced to curve on the drum. If they are removed from the drum, they may "flatten back" a bit since they were flat plates at the start.

In case 2, the plates stay curved when they are removed from the Stickney drum.

Also it would be interesting to know the thickness of the plates. Were flat plate steel plates used for flat plate presses thicker that flat steel plates used for rotary presses? What was the average thickness of a plate in those days, anyways? I have not found a specific number yet.. |

Send note to Staff

|

|

|

Valued Member

195 Posts |

|

|

Unkjay, thank you for sharing your insights.

I left out many details from my initial post for sake of keeping things simple. My main interest was in getting insight into what may have caused the "bruising," as I characterized it. Since the 1920s there has been much scholarship dedicated to deciphering the manufacture of the plates for the stamps from the 1851–1860 series. One theory has it that the various denominations were entered into the plates using multiple relief transfer rolls. In the case of the 30¢ stamp it is thought that a 4-relief roll was used. There is overwhelming evidence to demonstrate that the bottom of each relief was burnished to remove the bottom frame line from the stamp designs. My take is that if metal was removed from the roll below each design, how would it be possible for that part of the roll to have indented the plate such that it would pick up ink and print. There is also the uniqueness or "fingerprint" of each smudge to consider here.

None of the studies on 1851–1860 plate manufacture float the idea that wax or other contaminent might be responsible for the smudging seen in the various denominations. I like this theory if for no other reason than it opens the door to discussion of possible alternatives for the existence of these markings.

Thank you again Unkjay.

|

Send note to Staff

|

|

|

Valued Member

United States

153 Posts |

|

|

Drkohler,

The information you have given me is quite helpful. I do not know the thickness of the plates. Or how they were curved to the enperson roller. This I will have to look into to find some answers for you. Once a master engravement plate is made it would have been used over and over again. So covering the plate with wax between uses would sound right. The transfering the design into a printing plate could indeed form ridges of soften meatal that had to be removed before it was harden. Then it would have to be removed by someone. You were saying about a Sattle roller where two curved plates were mounted in (used in a lot of older newspaper presses). I will find out how the plates was curved and post my findings.

You have given me a lot to think about and I have no quick answer for you. Give me a few days to research and think on the subject. I like mysteries and this one is making me think. |

Send note to Staff

|

|

|

Valued Member

United States

153 Posts |

|

|

Essay_proof,

Thank you for the information you was kind to add to drkohler's. This gives me something to think about and I will do so investigating. I will post what I find then we will talk. By putting more heads than one on this we will come up with something.

Thank you once again for this mystery it make me have to think. |

Send note to Staff

|

|

|

Valued Member

195 Posts |

|

|

Unkjay, thanks again. Below is some additional information regarding the manufacture and use of the 30¢ plate in particular which may be useful to you as you mull this over (as I mentioned, many of the other stamps from this series also exhibit ink smudges.) But before I begin I want to say that for helpful as drkohler's post is in laying out the steps for flat plate manufacture as it is generally known to philatelists, some of that information goes beyond the scope of my original question, and conflates practices from different eras. If it's OK with everyone, I'd like to see the discussion in this thread confined to the original topic as I started it.

The following information is something I can write about with authority. One plate was made for the 30¢ stamp of 1860, and it is documented that production of the plate commenced on June 28, 1860. The plate was complete enough by July 2 for the printer (Toppan, Carpenter, & Co.) to send the POD a partial proof sheet for approval. By July 11, the firm began printing the stamps from the plate, 200 subjects.

There existed at one time a proof sheet in black on either wove or india (thought to be contemporaneous with actual stamp production) of which the stamps exhibit the various smudges, though not in every row. Of the 10 rows of stamps, the lowest row is completely free of these marks as are two of the higher rows. (That sheet has subsequently been cut into individual plate proofs.) Additional proof sheets thought to be contemporaneous with stamp production also exhibit these smudges as do the issued stamps.

This same plate was used to print proofs on card in 1875, 1881, and at least 2 more times in subsequent years. All of these proofs exhibit the same markings in the same places.

So whatever it was on the plate that printed as "smudges" persisted for the life of the plate. |

Send note to Staff

|

|

|

Pillar Of The Community

United States

3073 Posts |

|

|

Quote:

So whatever it was on the plate that printed as "smudges" persisted for the life of the plate. Yes, this is a key question I have in my mind as well. If wax, or similar, were the cause, how likely is it that it would have lasted over time? Maybe these proof plates are not good examples, since not a ton of impressions were pulled from them as compared to regularly issued stamps. |

Send note to Staff

|

|

| |

Replies: 8 / Views: 671 Replies: 8 / Views: 671 |

|