| Author |

Replies: 90 / Views: 50,799 Replies: 90 / Views: 50,799 |

|

|

|

Rest in Peace

Netherlands

963 Posts |

|

|

Is James still interested in the photogravure vs recess thread???

It would be great to discuss a few stamps with him!

groetjes, Rein |

Send note to Staff

|

|

|

Pillar Of The Community

Canada

5417 Posts |

|

|

It is too bad that James hasn't posted anymore in over 2˝ years.

It would be great fun to have more of this kind off stuff

discussed on the forum in a separate section perhaps.

|

Send note to Staff

|

|

|

Pillar Of The Community

United States

3822 Posts |

|

|

Update - some gravure printing cylinders are now created with a digitally controlled diamond tip to produce the cells instead of the etching James described |

Send note to Staff

|

|

|

Valued Member

United Kingdom

304 Posts |

|

|

Eyeonwall: There are two basic methods that have been used down the years...

GRAVURE STYLUS ENGRAVING:

A steel cylinder base is coated with copper by means of electro-plating. The cylinder is then loaded onto the EME machine after polishing. The individual ink cells (of varying depths) are engraved by a computer-controlled diamond stylus driven by electro-mechanical pulses, one cylinder per colour (CMYK plus, maybe, extra spot colour(s)). The stylus cuts away the copper, much like the use of a burin by an intaglio engraver.

GRAVURE LASER ENGRAVING:

A steel cylinder base is coated with copper and then further coated with a zinc layer by means of electro-plating. The cylinder is then loaded onto the EME machine after polishing. The individual ink cells (of varying depths) are engraved by a computer-controlled laser beam, one cylinder per colour (CMYK plus, maybe, extra spot colour(s)). Direct laser engraving is especially useful for reproduction of soft vignettes. Unlike the stylus method of engraving, the laser beam does not actually touch the cylinder.

GLENN

|

Send note to Staff

|

|

|

Pillar Of The Community

United States

3822 Posts |

|

|

Glenn M? - thanks - makes sense that they can also use lasers. (I used to work in an industry where lasers were used to make tiny volcano shaped marks in a metal part. |

Send note to Staff

|

|

|

Pillar Of The Community

United States

795 Posts |

|

|

Rest in Peace

Netherlands

963 Posts |

|

|

As to the types of photogravure screens James described, we missed the "unscreened" or "screenless" type!

The regular screens can also be divided into cross-type and brick-type, each with the option of different densities. And that also goes for the EME-type.

The cross-type screens are either depth-variable i.e. the surface is the same, but the depth of the cells vary OR surface-variable where the depth of the cells is always the same and the surface varies. The surface variable screen is sometimes referred as by Autotypical screen and it basically the same type as used for offset-litho and typography.

I will post some scans here soon to make things clear!

Another aspect of recess printing is that it does not has to have an engraving! Quite often the images are etched - a method started around 1950 by the Dutch firm of JOHEZ [Joh. Enschedé en Zonen, Haarlem].

|

Send note to Staff

|

|

|

Rest in Peace

Netherlands

963 Posts |

|

|

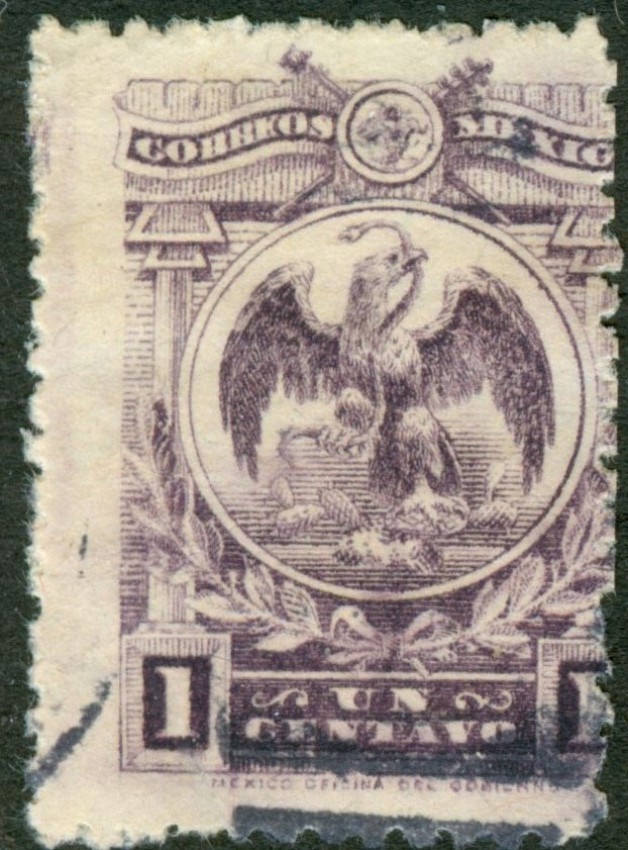

Since 1916 and before 1936 the Mexican stamps were printed by the Oficina Impresora de Hacienda [State Printing Works] in recess/intaglio or in a very similar process that resembled more the later photogravure. As a matter of fact they used both the traditional recess AND the adapted process for the very same stamps! In other words they were experimenting with the printing process and eventually went on with what we now know as photogravure. From 1936 the TIEV [Talleres de Impresion de Estampillas y Valores] took over using the same process [unscreened photogravure] on the newly imported printing press made by GOEBEL, Darmstadt, Germany. The history of the Mexican stamps as to their printing methods has not really been written up to now. It is thinkable that even the experts writing catalogues like Celis Cano had no idea about the richess of Mexican stamp printing history. the traditional version:   The unscreened version:   ***Mod fixed images*** ***Mod fixed images*** |

Send note to Staff

|

|

|

Rest in Peace

Netherlands

963 Posts |

|

|

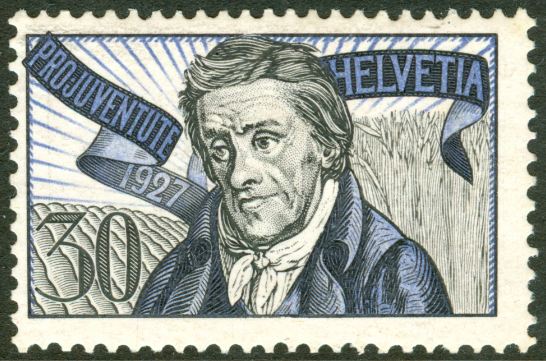

The break-through for screenless photogravure came from the Dutch firm "Nederlandsche Rotogravure Maatschappij" in my home-town of Leiden.

They had already introduced photogravure in the British firm of Harrison and Sons in 1922/1923 and helped them out in printing most of the King Fuad stamps of Egypt. All with the granular screen as James showed us!

The NRM did closely work together with the German machine builder Goebel AG, Darmstadt. Soon after printing two Swiss stamps in screenless photogravure, the NRM and Goebel introduced photogravure rotary presses in Italy [Instituto dell Stato, Rome] and in South Africa [State Printers, Pretoria] where several face values of the Vatican definitives respectively all definitives of Sout Africa got printed screenless! |

Send note to Staff

|

|

|

Rest in Peace

Netherlands

963 Posts |

|

|

Rest in Peace

Netherlands

963 Posts |

|

|

Rest in Peace

Netherlands

963 Posts |

|

|

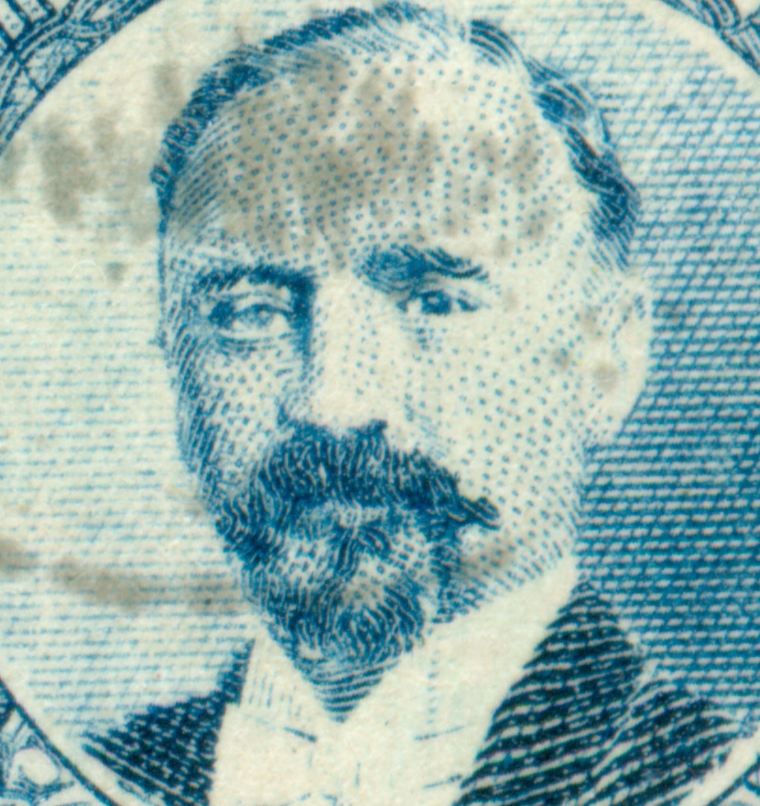

At least 2 values seem to have had both engraved [steel-engraving?] and etched [copper-etching?] plates: 5c Maclovio Herrera:   10c Francisco Madero:   the 5c has a completely different design and there is no name mentioned! |

Send note to Staff

|

|

|

Pillar Of The Community

Canada

5417 Posts |

|

|

Rein are you sure that the "Nederlandsche Rotogravure Maatschappij" printed this stamp?  Michel shows # 225 printed Photogravure by Eidgen.Münze (Eidgenössische Münze(Swissmint) |

Send note to Staff

|

|

|

Rest in Peace

Netherlands

963 Posts |

|

|

Absolutely sure!

NRM no doubt about it!

|

Send note to Staff

|

| Edited by Galeoptix - 02/11/2014 6:30 pm |

|

|

Valued Member

United Kingdom

304 Posts |

|

|

I am really struggling with the whole concept of screenless photogravure. I have read with great interest the various bits here and there about this matter, but am no clearer.

Normally, cells in gravure printing exist to hold the ink and are of variable depth to give darkness or lightness of colour where needed. So if a stamp is printed by screenless photogravure, how is the ink prevented from simply flowing across the whole surface of the cylinder? And why does the doctor blade not clean all of the ink off of the surface without the recesses in the cylinder?

Rein mentions in another blog back in 2007: "The screenless photogravure was their (NRM, Leiden) secret process that they sold Goebel AG, Darmstadt, Germany. The first reel-fed photogravure printing presses sold by Goebel to State Printers were performing with screenless photogravure cylinders"

I wonder if Rein could perhaps please explain in simple terms how this process worked - or is it still a secret to this day?

Many thanks.

GLENN

|

Send note to Staff

|

|

Replies: 90 / Views: 50,799 Replies: 90 / Views: 50,799 |

|